When you're trying to decide between fiber cement siding and vinyl, it really boils down to what you value most: premium durability and aesthetics, or upfront affordability and easy maintenance. Fiber cement brings incredible strength and a high-end, wood-like look that stands up beautifully to our unique Pacific Northwest weather. On the other hand, vinyl is a wallet-friendly, low-effort solution available in a huge range of colors. For most Seattle homeowners, the choice is a classic tug-of-war between long-term investment and immediate savings.

Choosing the Right Siding for Your Seattle Home

Picking an exterior for your home is a big deal, especially here in the Pacific Northwest. Our unique climate—with its persistent moisture and see-sawing temperatures—demands a siding that doesn't just look good, but also offers serious, long-lasting protection. A siding replacement is far more than a simple facelift; it's a crucial investment in your home's health and structural integrity, forming the first line of defense against our damp environment.

This guide is designed to give you a practical way to compare these two siding giants. We'll focus on the things that matter most to anyone living in the Seattle area:

- Weather Durability: How does each material really handle our constant dampness and temperature swings?

- Aesthetic Versatility: What kind of design flexibility does each option give you to match your home’s style?

- Long-Term Maintenance: What's the real-world upkeep required to keep your siding looking great year after year?

- Total Cost of Ownership: We'll look beyond the initial price tag to understand the full financial picture over time.

Siding Preferences Across the Nation

While our local climate is the top priority, it's interesting to see how these materials stack up nationally. According to the U.S. Census Bureau’s Survey of Construction, vinyl and fiber cement were nearly neck-and-neck in 2021 for new single-family homes, with vinyl used on 24% and fiber cement on 23%.

But here's where it gets interesting: vinyl's popularity skyrockets in colder, northern climates. It was used on a whopping 66% of new homes in New England and 74% in the Middle Atlantic. You can dive into the full research about these siding trends to see just how much region matters.

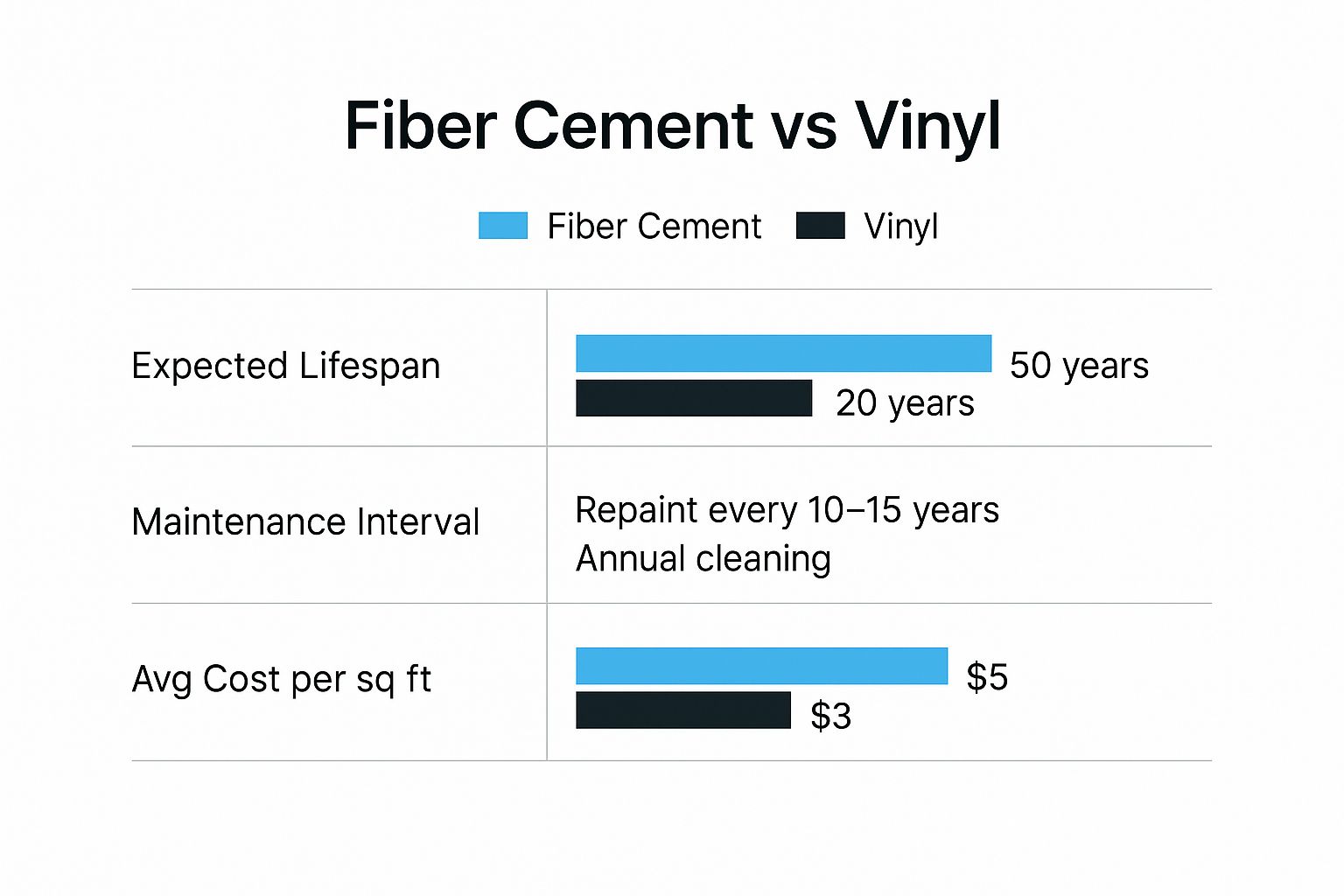

This infographic gives a great visual breakdown of the core differences between the two.

The numbers make it clear: while vinyl has a lower upfront cost, fiber cement's significantly longer lifespan makes it a powerful long-term investment. Grasping these key trade-offs is the first and most important step to making a decision you'll be happy with for decades.

Durability and Weather Resistance in the Pacific Northwest

Let's be honest, siding in the Pacific Northwest takes a beating. The relentless dampness—the rain, the mist, the morning dew—is a constant battle for your home's exterior. It’s the ultimate test track for building materials, and when it comes to fiber cement siding vs vinyl, how they handle our climate couldn't be more different.

Fiber cement was practically made for this kind of weather. Its mix of cement, sand, and cellulose fibers doesn't really absorb moisture. That’s a huge deal here because it means the siding won’t swell up, rot, or warp from the near-constant exposure to rain we get in Seattle. This stability is absolutely critical for the long-term health of your home.

Vinyl siding is also waterproof, which is good. Its PVC makeup means water just beads up and rolls off. The issue, though, is with the installation. Vinyl has to be hung loosely to let it expand and contract, and this can leave small gaps. In our humid climate, moisture can find its way behind the panels, and if it gets trapped, you're looking at a potential breeding ground for mold and mildew on your home's structure. Meticulous installation with proper flashing and house wrap is non-negotiable here.

Impact and Temperature Stability

Our weather isn't just a one-trick pony; we get gusty windstorms and our fair share of temperature swings. Think about the debris from our towering evergreens or the occasional hailstorm—impact resistance suddenly becomes a big deal. Fiber cement is a much thicker, more rigid material, giving it a real edge in shrugging off hits from falling branches or other projectiles.

Vinyl, on the other hand, is a softer, more flexible material. While it can bounce back from minor bumps, it tends to get brittle in the cold. A sharp impact on a frosty morning could easily crack or puncture a vinyl panel, forcing you to replace it.

For Seattle homeowners, the key differentiator is stability. Fiber cement remains dimensionally stable through our region's temperature swings, whereas vinyl will noticeably expand and contract. This movement must be accounted for during installation to prevent buckling or warping over time.

The Ultimate Test: Fire and Pest Resistance

Beyond wind and water, we have other local challenges to think about. Pests like termites and carpenter ants are always a concern. The good news is that fiber cement offers them nothing to eat. It's an inert material, making it pretty much immune to insect damage.

Vinyl also gets a passing grade here. Pests can't digest the plastic, so both options have a clear advantage over traditional wood siding in this department.

But here’s where the two materials really part ways: fire resistance. Fiber cement is non-combustible. It carries a Class 1(A) fire rating, which is the best you can get. It simply won't ignite or add fuel to a house fire. Vinyl siding, however, will melt and can release toxic fumes when it burns. For anyone putting a premium on safety, that's a make-or-break difference.

Aesthetics and Design Flexibility for Your Home

More than any other feature, your home's siding is its public face—it sets the tone and defines its curb appeal. When you're weighing fiber cement siding vs vinyl, you're really looking at two very different paths to achieving your desired style. This choice goes far beyond color; it’s about texture, depth, and how authentically the material complements your home's architecture.

If you’re aiming for the rich, detailed appearance of natural materials, fiber cement is hands-down the champion. Its unique composition can be molded to convincingly imitate the deep grain of cedar, the clean look of modern smooth panels, or even the texture of stucco. For Seattle’s diverse neighborhoods—from historic Craftsman homes to sleek, contemporary builds—this versatility is a massive advantage.

The Power of Authentic Textures

The real aesthetic difference comes down to the material's substance. Fiber cement panels are much thicker and more rigid than their vinyl counterparts, which allows for deeper embossing and sharper, more defined edges. This creates dramatic shadow lines that give your home a sense of permanence and weight, much like traditional wood siding but without all the maintenance headaches.

On the other hand, vinyl siding offers an incredible variety of factory-applied colors and profiles right out of the box. Modern manufacturing has come a long way, and you can find everything from traditional lap siding to the popular board and batten style. Its main appeal is convenience. Since the color is baked in, you'll never have to pick up a paintbrush. Still, the thinner nature of vinyl means the textures are shallower and the shadow lines are less pronounced, which can sometimes look less convincing up close.

Elevating the Look with Professional Details

Regardless of your choice, the final look hinges on the finishing touches. Any experienced installer will tell you that the trim, corners, and window casings are what separate a standard siding job from a truly exceptional one.

A trade secret for a high-end finish with either material is to invest in a premium trim package. Using thicker, more substantial trim boards around windows and doors gives the whole project a polished, custom-built appearance that looks more deliberate and expensive. It's the difference between a standard job and a showpiece.

With fiber cement, this often involves using complementary composite trim that can be painted to match or contrast with your siding. For vinyl, specialized corner posts and J-channels are required. While the standard options do the job, upgrading to more decorative trim profiles can make a world of difference. To see how these details come together, take a look at our gallery of completed siding projects.

Ultimately, fiber cement gives you unmatched design freedom, while vinyl delivers a reliable and vast palette of maintenance-free options.

Comparing Total Cost of Ownership

When you're weighing the cost of a siding replacement, just looking at the price per square foot is a classic mistake. It's like judging a car by its paint job—it doesn't give you the full picture. The smart way to look at it is through the lens of total cost of ownership. This means factoring in everything: the initial installation, the maintenance you'll do over the years, and what you get back when you sell. That's where you'll find the real answer in the fiber cement siding vs vinyl debate.

On paper, vinyl siding always looks like the winner for upfront cost. The material is cheaper, and installation is quicker and less demanding on the crew. For anyone on a tight initial budget, it’s a really compelling option.

But the higher sticker price on fiber cement has a story behind it. This stuff is heavy, and you need a specialized, experienced crew with the right tools to hang it properly. That initial investment in quality labor is what guarantees the siding will actually last its full 50+ year lifespan.

Long-Term Expenses and ROI

The financial narrative really starts to change when you fast-forward a decade. Fiber cement will need a new coat of paint every 10 to 15 years, and that’s a real expense to plan for. Vinyl, on the other hand, never needs painting. A good cleaning once a year is all it takes to keep it looking fresh.

But what about when things go wrong? If a piece of vinyl cracks from an impact, the whole panel has to come out. Trying to find a new panel that perfectly matches the color of your sun-faded siding can be a real headache. Fiber cement is tougher to damage in the first place, but if a small area gets dinged, you can often patch and repaint it without a trace.

For most Seattle homeowners, the bottom line is return on investment (ROI). Siding replacement is one of the smartest upgrades you can make to your home, and your choice of material heavily influences how much value you add. It's a key benefit that often gets overlooked.

Market Value in the Seattle Area

In a hot real estate market like Seattle, quality materials make a difference. Vinyl siding provides a decent return, no doubt. But the robust feel and upscale look of fiber cement often create a higher perceived value for potential buyers. Its knack for beautifully mimicking traditional wood siding is a perfect fit for the classic architectural styles we see all over the Pacific Northwest.

Looking at the bigger picture, vinyl's low cost has made it a global favorite. In 2023, it captured a 24% share of the entire siding market, and homeowners who installed it saw an average 80.2% of their money back at resale. Still, if you're planning to stay in your home for the long haul or want to maximize your home's value in a sophisticated market like ours, fiber cement’s endurance and curb appeal often make the higher initial cost a worthwhile investment. You can dive deeper into the global siding market and its trends to see the full scope.

Maintenance and Long-Term Upkeep Requirements

Choosing your siding is about more than just looks and durability—it’s about signing up for a certain level of long-term commitment. When you put fiber cement siding vs vinyl head-to-head on upkeep, you’re really looking at two completely different philosophies: one is about occasional, simple cleaning, while the other requires more proactive, periodic work. Knowing what you're getting into for the next few decades is key to making a smart choice.

Vinyl siding has a reputation for being incredibly easy to care for, and for the most part, it's well-deserved. For most of us here in Seattle, a yearly wash-down with a garden hose and a soft brush is enough to get rid of the pollen, dirt, and mildew that our climate is famous for. It’s a simple routine that keeps your home looking sharp without any special tools or skills.

The catch with vinyl, however, is its vulnerability to impact. An errant baseball, a misplaced ladder, or a falling branch can easily crack or puncture a panel. This is especially true during colder months when the material gets more rigid and brittle.

Professional Repair Techniques

Fixing a damaged vinyl panel isn't as simple as slapping on a patch. While some homeowners might try a DIY approach, professionals rely on a specific tool called a zip tool to neatly unlock the damaged panel from the ones above and below it. This allows for a clean removal and replacement, ensuring the new piece snaps in securely and your home's weather barrier stays intact.

Here's a pro tip I always give vinyl siding owners: stash away several extra panels from the original installation. Trying to match the color of a new panel to siding that has been exposed to years of sun and rain is next to impossible. Having those original pieces is the only way to get a repair that doesn't stick out like a sore thumb.

Fiber Cement Upkeep and Best Practices

Fiber cement, on the other hand, is a much tougher material but it does ask for a different kind of maintenance. The biggest task you'll face is repainting, which typically needs to be done every 10 to 15 years. While it's a bigger project than hosing down vinyl, it’s also a fantastic opportunity to completely change up your home's color and curb appeal.

But the most crucial part of fiber cement maintenance, especially in a place as wet as Seattle, is keeping an eye on the caulk. The sealant around the joints, corners, and windows is what keeps moisture out. You'll want to give these seals a quick inspection every year, looking for any signs of cracking or pulling away. If you spot a problem, scrape out the old caulk and apply a fresh bead of high-quality, flexible sealant. It's a small, proactive step that prevents water from sneaking in and causing serious damage down the line.

Making Your Final Siding Decision

https://www.youtube.com/embed/uyUSS_cTZbU

Choosing between fiber cement and vinyl siding really boils down to what you value most for your home. There’s no single right answer, just the best choice for your specific situation—your budget, your aesthetic goals, and how much work you're willing to put in over the years.

Let's break it down to help you find the perfect fit. Think about what's driving your decision: is it the initial price tag? The look you've always wanted? Or maybe it's the idea of low-maintenance living? Weigh those against the realities of our Seattle climate, and you'll find your answer.

When to Choose Vinyl Siding

Vinyl siding is often the go-to choice when the decision hinges on two key things: upfront budget and minimal upkeep. It's a straightforward, affordable way to get your home protected and looking sharp without a drawn-out or costly installation. If a "set it and forget it" exterior sounds good to you, vinyl's simple annual wash is a huge selling point.

Vinyl is probably your best bet if you're:

- Working with a tighter budget right out of the gate.

- Looking for a siding that only needs a good rinse-down once a year.

- Wanting a wide range of colors that come straight from the factory, no painting required.

- Okay with a lifespan of 20-30 years and understand it can become brittle in very cold weather.

When to Choose Fiber Cement Siding

On the other hand, fiber cement is the champion if you're playing the long game, focusing on maximum durability, an authentic look, and boosting your home's value. This stuff is built to handle everything the Pacific Northwest throws at it, from our signature dampness to those unpredictable temperature swings. Plus, its ability to convincingly replicate real wood gives your home a premium curb appeal that really stands out in the Seattle market.

If you see your house as a long-term home or want to squeeze every bit of value out of it when you sell, fiber cement is hard to beat. Its 50+ year lifespan and solid, high-end appearance deliver a powerful return on investment.

You should lean toward fiber cement if you:

- Want best-in-class protection against moisture, pests, impact, and fire.

- Love the deep shadow lines and classic appearance of real wood siding.

- Are making a long-term investment in your property and its resale value.

- Are prepared for a higher initial cost and the need to repaint every 10-15 years to keep it looking fresh.

Siding FAQs: Your Questions Answered

Even after weighing the pros and cons, you probably still have a few specific questions about fiber cement and vinyl siding. It’s a big decision. Let’s tackle some of the most common things we hear from Seattle homeowners to help you feel confident in your final choice.

How Does the Installation Process Differ?

These two materials couldn't be more different when it comes to installation. Vinyl siding is lightweight, flexible, and designed to be hung from the house using a locking system. This approach is quick, forgiving, and allows the panels to expand and contract with temperature changes.

Fiber cement is a different beast entirely. It’s heavy, rigid, and can be brittle before it’s installed. It takes a specialized crew with diamond-tipped blades to cut it precisely and manage the silica dust safely. The panels are then nailed directly to the home, similar to wood siding, which is a much more labor-intensive process that contributes to its higher initial cost. This is why choosing a highly experienced crew is the most important factor for a successful fiber cement installation.

Is One Siding Option More Environmentally Friendly?

Honestly, both materials have their own environmental story. Fiber cement’s biggest green credential is its incredible lifespan—often lasting 50 years or more. It’s made from sustainable materials like sand, cement, and wood pulp, and because it lasts so long, it dramatically cuts down on replacement waste.

Vinyl is made from PVC, a petroleum product, but manufacturing has become much more efficient. It’s lighter to ship, which cuts down on transportation emissions, and many modern vinyl products are recyclable. The best choice here really depends on your priorities: do you value durable, natural-based materials (fiber cement) or manufacturing efficiency and recyclability (vinyl)?

Can I Paint Vinyl Siding If I Want a New Color?

Yes, you can paint vinyl siding, but you have to do it right. You'll need a high-quality, "vinyl-safe" acrylic paint that's specifically made to flex with the siding as it moves.

Here's the most important thing to know about painting vinyl: you must choose a color that is the same shade or lighter than the original. Going darker will cause the vinyl to absorb too much heat, which can lead to warping, buckling, and permanent damage.

While it’s an option, remember that one of the best things about vinyl is its baked-in, low-maintenance color. Painting it introduces a new maintenance cycle that vinyl was originally designed to help you avoid.

Ready to transform your Seattle home's exterior with siding that’s built to last? The experts at Breeze Siding are here to help you navigate every step of the process, from choosing the right material to flawless installation. Visit us at https://breezesiding.com to schedule your free, no-obligation estimate today.