When it comes to siding for a Seattle home, the conversation almost always boils down to two main contenders: Hardie Board versus vinyl. The decision really hinges on what you value most—durability against our notoriously damp weather or the upfront cost.

Hardie Board is the premium, moisture-resistant choice that’s practically tailor-made for the Puget Sound, while vinyl brings a budget-friendly ease and remarkably low upkeep to the table. This guide will walk you through the trade methods, best practices, and real-world benefits of a siding replacement, helping you figure out which material truly aligns with your home and your goals.

Quick Guide for Seattle Homeowners

Let's start with the factors that matter most in the Pacific Northwest. You can get a good feel for your best option just by looking at these core differences.

- Hardie Board Siding: This is your go-to for unmatched moisture resistance. With a potential 50-year lifespan, it’s a long-term investment built to withstand Seattle’s damp climate without batting an eye. Its baked-on ColorPlus Technology also means the rich hues won't fade under our often-gray skies. A key benefit of siding replacement with Hardie is the immediate upgrade in your home's defense against rot and pests.

- Vinyl Siding: If your budget is a primary concern, vinyl is tough to beat. Starting around $3–$7 per square foot, it eases the initial financial burden while still offering very low maintenance. The lightweight panels and simple snap-fit design also make for a much quicker and less labor-intensive installation—a major benefit if you're on a tight timeline.

Hardie Board vs Vinyl At a Glance

For a straightforward, side-by-side look, this table breaks down the essential differences. It's the perfect tool for a quick gut check on which material fits your needs.

| Attribute | Hardie Board Siding | Vinyl Siding |

|---|---|---|

| Typical Cost | $10–$15 per sq. ft. installed | $3–$7 per sq. ft. installed |

| Durability | High resistance to moisture, rot, pests, and fire. Won't warp. | Moderate. Can become brittle and crack in freezing temps; may warp. |

| Maintenance | Low. Repainting is needed every 10–15 years unless you have ColorPlus. | Very low. An annual power wash is usually all it needs. Damaged panels must be replaced. |

| Appearance | Authentic wood-like texture. Available with a baked-on color finish. | Smooth, plastic look. Comes in a wide range of colors. |

| Lifespan | Up to 50 years. | Typically 20–40 years. |

At the end of the day, both have their place in the Seattle market. The best choice really comes down to what you're trying to achieve with your project.

"In Seattle’s humidity, Hardie Board holds up far better than vinyl, but budget projects still benefit from vinyl’s simplicity."

– Local siding installer from Breeze Siding

Making the Call: Which Siding Fits Your Priorities?

Think about what's driving your decision. Your answer will point you in the right direction.

- Looking for long-term value and serious curb appeal? Hardie Board is almost certainly your best bet.

- Need a cost-effective solution with a fast installation? Vinyl siding is the clear winner here.

- Worried about color fading over time? Hardie Board’s ColorPlus finish is specifically designed to resist UV damage and fading.

- Hoping for a DIY-friendly option? Vinyl is lighter and more forgiving to work with, requiring fewer specialized tools.

This quick overview should help you narrow down your choices right from the start. As we move on, we'll dig much deeper into climate resilience, return on investment, and the specific installation methods required for each.

Consider this your roadmap. Whether you lean toward the robust strength of fiber cement or the practical simplicity of vinyl, the rest of this guide will give you the detailed information you need to make a confident choice for your Seattle home.

Surviving Pacific Northwest Weather: The Durability Test

When we talk about Hardie board siding vs. vinyl, durability in the Pacific Northwest isn't just a selling point—it's the whole ballgame. Our climate throws a unique combination of relentless rain, pervasive humidity, and surprising temperature swings at our homes. A siding material that looks great in a dry, sunny state can fail spectacularly here in places like Bellevue, Redmond, or Tacoma.

This is where the real differences between Hardie board and vinyl siding start to show. You can see a clear trend among homeowners prioritizing materials that can actually stand up to our specific environmental pressures. In fact, the market share for fiber cement siding on new homes has nearly tripled since 2003, largely because of its resilience in demanding climates like ours. You can dig into the numbers yourself in this siding market analysis from NAHB.org.

It's a shift that shows people want more than just a pretty exterior; they want a tough, reliable shield against the elements.

Hardie Board’s Fortress Against Moisture

Think of James Hardie siding as a fortress built specifically for the wet Pacific Northwest. Its makeup—a mix of cement, sand, and cellulose fibers—creates a dense, non-porous material that simply doesn’t soak up water the way wood does. In a region where moisture is the enemy, that's a massive advantage.

Because water can't penetrate, the risk of rot, swelling, and warping gets taken right off the table. A key benefit of siding replacement is the opportunity to install a new, high-performance weather-resistive barrier (WRB) or rainscreen system underneath the siding, creating a comprehensive moisture management system that protects your home's structure. On top of that, Hardie's inorganic composition makes it completely uninteresting to pests like termites and carpenter ants, which are a constant headache for wood-sided homes around Seattle.

"We get called out to repair siding failures all the time. With vinyl, it's often cracking from a cold snap or warping where the sun hits it hard. With Hardie, if there's a problem, it's almost always an installation error—bad flashing or improper gaps. The material itself rarely fails."

– Lead Installer, Breeze Siding

Vinyl Siding’s Vulnerability to Temperature Swings

Vinyl siding, being made from PVC, actually handles direct moisture quite well—rain just beads up and rolls right off. Its real weakness in our climate, however, is its reaction to temperature changes. Vinyl is designed to expand in the summer heat and shrink in the winter cold, a process called thermal expansion and contraction.

If it's not installed with this movement in mind, you're in for trouble. Panels nailed too tightly will buckle and warp on a hot day, creating an ugly, wavy look. Then, when a sudden Puget Sound cold snap hits, the material becomes brittle and can easily crack from a minor impact, like a stray baseball or a hailstorm.

Common Vinyl Failure Points in the PNW:

- Cracking: In freezing temperatures, vinyl becomes brittle and can shatter or crack.

- Warping: If installed without room for expansion, it can buckle, especially on walls that get a lot of direct sun.

- Fading: While modern vinyl has UV protection, darker colors are still prone to fading over the years, which can make your house look patchy.

This is exactly why professional installation is non-negotiable for vinyl. A seasoned contractor knows to hang the panels loosely, letting them "float" so they can move freely as the temperature changes. It’s a small detail that makes the difference between a siding job that lasts decades and one that looks terrible after a few years.

The Real-World Performance Comparison

So, let's step away from the material science and look at how these two products actually hold up, year after year, on real Seattle-area homes. The durability debate in the Hardie board siding vs. vinyl conversation isn't just about what they're made of, but how they behave in our environment.

Hardie board's sheer rigidity and weight give it far better impact resistance. It can handle wind-driven debris from a storm or an errant soccer ball from the kids without denting. Plus, its factory baked-on color finish is engineered to resist fading from our sometimes-surprisingly-strong UV rays, keeping its curb appeal for much longer.

Vinyl is a thinner, more flexible material, which makes it more susceptible to dents and punctures. While it’s a breeze to clean, a solid impact often means replacing an entire panel. And good luck getting a perfect color match if the rest of your siding has already started to fade. Ultimately, the right choice comes down to balancing the upfront cost with how much long-term resilience you need for the unique challenges our Pacific Northwest weather throws at us.

Breaking Down the True Cost and Return on Investment

https://www.youtube.com/embed/ZqHxTKE712g

When you’re weighing Hardie board siding vs vinyl, the conversation usually kicks off with the price tag. But the real financial story runs much deeper than the initial quote—it's about the total cost of ownership over the decades you'll live in your home. For homeowners in the Seattle area, this means looking past the upfront sticker shock to see the long-term value in our competitive real estate market.

The initial cost gap is pretty clear. Vinyl siding is the undisputed budget-friendly option, typically landing between $3 to $7 per square foot installed. Hardie board, on the other hand, is a premium product, and its price reflects that, usually running between $10 to $15 per square foot installed.

That difference isn't random. It’s a direct result of the materials themselves, the product's weight, and the specialized skills needed to get the installation just right.

Understanding the Upfront Installation Costs

Vinyl’s lower price point comes from its lightweight nature and a more straightforward installation process. The material is cheaper to produce, and the snap-together panels don't require the same specialized tools or large crews. This efficiency directly cuts down on labor costs, and a good team can often wrap up a vinyl job much faster than a fiber cement one.

Installing Hardie board is a whole different ballgame. The planks are heavy, and they can be brittle before they're on the wall. They also require special saws to safely manage silica dust. More importantly, the installation demands a higher level of precision to ensure the proper clearances and flashing are in place—details that are absolutely critical for preventing moisture damage here in the Pacific Northwest. That complexity means you'll pay more for a certified, experienced crew, but it’s an expense that truly protects your investment.

Factoring in Long-Term Maintenance and Lifespan

This is where the financial equation starts to even out. Vinyl is incredibly low-maintenance; a quick wash once a year is usually all it needs. The downside? Its color is baked into the material, so if a panel gets a deep scratch or cracks, you can't just patch it up. The whole piece has to be replaced, and trying to find a perfect color match a few years down the road can be a real headache.

Hardie board, especially with the factory-applied ColorPlus Technology, holds its color remarkably well for years. The main long-term maintenance task is repainting, typically every 10 to 15 years, to keep it looking sharp. While that’s an extra cost, it's a predictable one you can plan for, not a surprise repair.

For Seattle homeowners, the return on investment isn't just about saving a few bucks on maintenance. It's about boosting curb appeal and resale value in a market that rewards quality and durability. Hardie board’s authentic, wood-like appearance gives it a definite edge here.

The Real-World Return on Investment in Seattle

In the discerning Seattle real estate market, curb appeal has a real, measurable impact on a home's price. A siding replacement project already delivers one of the highest ROIs of any home renovation, but the material you choose can seriously amplify that return.

Here’s how I see it break down for different goals:

- For Rental Properties or Budget-Focused Flips: Vinyl often makes the most sense. Its low initial cost and minimal upkeep help maximize your immediate profit margins.

- For Your "Forever Home" or a High-End Resale: Hardie board is usually the smarter long-term play. Its premium look can dramatically lift your home’s perceived value and attract more serious buyers.

This isn't just a local trend. While vinyl is still a popular choice for renovations across North America, fiber cement's market share in new construction has jumped by over 14 percentage points in the last two decades. That's a strong signal that builders and new homeowners are prioritizing durability and a premium look. You can dig into the numbers in this U.S. siding market analysis.

In the end, the best financial decision in the Hardie board siding vs vinyl debate comes down to what you're trying to achieve. Vinyl gives you immediate savings and practicality, while Hardie board is a lasting investment in your home’s beauty, resilience, and market value.

Getting the Installation Right is Everything

Here’s the hard truth: the difference between a siding job that lasts 50 years and one that fails in five often comes down to the quality of the installation. When it comes to Hardie board siding vs vinyl, how the material gets put on your house is just as critical as the material itself. This is especially true here in the Pacific Northwest, where a single installation mistake is an open invitation for our relentless rain to get in and cause real damage.

Understanding how each product should be installed helps you know what to look for and ensures you get the performance you’re paying for. The techniques for Hardie Board and vinyl are worlds apart, and both have non-negotiable best practices that can't be ignored.

The Craftsmanship of Hardie Board Installation

Installing Hardie Board isn't just a construction job; it's a craft. It demands precision, specialized tools, and a deep understanding of water management. Because fiber cement is so heavy and rigid, you need a crew that knows how to handle it without chipping or cracking the boards.

The work requires special equipment, from saws with dust-collection systems (to manage silica dust) to specific nail guns that won't overdrive the fasteners and compromise the material. But most importantly, a successful installation in our wet climate hinges on perfect flashing and clearances. Installers absolutely must leave precise gaps around windows, doors, and rooflines, and then flash these areas correctly to shed water away from your home's structure. A best practice we always follow is a "kick-out flashing" where a roofline meets a wall—it’s a small detail that prevents a huge amount of water damage over the years.

A common mistake we see is when installers don't leave the required gap between siding courses and the roofline. That small oversight allows water to wick up into the material, compromising the entire siding system over time.

This meticulous process is why James Hardie has a Preferred Installer program. Choosing a certified contractor like Breeze Siding means your team has been trained by the manufacturer on these exact details, which protects your investment and keeps your warranty intact. For Hardie Board, professional installation isn't just a good idea—it's essential.

Nailing the Nuances of Vinyl Siding

Vinyl siding installation is less about brute force and more about finessing a material that is designed to move. The biggest secret to a great vinyl job is properly accounting for thermal expansion and contraction. Vinyl will naturally grow a bit in the summer sun and shrink in the winter cold.

A pro installer never nails vinyl panels tightly to the wall. Instead, they "hang" each panel, leaving the fasteners slightly loose in the center of the nailing slots. This simple step allows the panels to slide back and forth as temperatures change. Skipping this is exactly what causes the ugly buckling, warping, and wavy look you see on poorly installed homes. It's a small detail that makes all the difference.

Because it's so lightweight and forgiving, vinyl can be a more approachable project for a skilled DIYer. But getting the details right is still critical to avoiding long-term headaches. While its ease of installation keeps it a popular choice for renovations, recent siding market trends and consumer choices show a clear shift in new construction toward more durable materials like fiber cement.

A Contractor Checklist for Seattle Homeowners

Hiring the right team is the single most important decision you'll make for your siding project. A great contractor delivers a flawless finish and, more importantly, protects your home from the elements for decades to come.

Before you sign any contract, be sure to ask these critical questions:

- Are you licensed, bonded, and insured in Washington? This is non-negotiable. It’s for your protection.

- Are you a James Hardie Preferred Installer? If you're going with fiber cement, this certification is a crucial indicator of expertise.

- How do you handle flashing around windows and doors? A good answer will get into specific techniques for our rainy climate, like using integrated flashing systems or Z-flashing above trim boards.

- What’s your process for job site cleanup? A professional crew respects your property from start to finish.

Asking the right questions upfront will help you find a team that truly understands what it takes to install siding correctly in the Pacific Northwest.

Comparing Aesthetics and Architectural Style

Your siding is the face of your home—it’s what defines its character and gives it curb appeal. When you're weighing Hardie board siding vs vinyl, the visual differences are probably the first thing you'll notice, and they're a huge factor in how your home will look in its Seattle neighborhood.

The biggest distinction comes down to texture and thickness. Hardie board is significantly thicker and more rigid than vinyl, which allows for much deeper, more authentic-looking wood grain patterns. That extra thickness also creates deeper shadow lines, giving the siding a substantial, premium feel that really does look like traditional wood or cedar shake.

Hardie Board for Authentic Seattle Architecture

This quality makes Hardie an almost perfect match for many of Seattle’s iconic home styles. Think about the classic Craftsman homes you see in Queen Anne or Capitol Hill. Hardie’s ability to mimic the look of traditional wood lap siding or shingles is a game-changer for preserving that architectural integrity while getting modern durability. It just looks high-end.

It’s not just for historic homes, either. For the sleek, modern designs popping up in Ballard or West Seattle, the crisp, clean lines of smooth Hardie panels or the bold look of a board-and-batten style are fantastic. The material’s rigidity means you get perfectly straight lines, which is exactly what a minimalist aesthetic demands.

Vinyl Siding and Its Place in Modern Homes

Vinyl siding, on the other hand, offers a much more uniform and consistent look. Manufacturers have gotten better with texturing over the years, but it still doesn't quite capture the realistic wood grain or depth of fiber cement. Because it’s thinner, the shadow lines are shallower, which can sometimes make it look a bit flat up close.

But don’t count it out. Vinyl’s smooth finish and massive color selection make it a really practical choice for many contemporary homes, ranches, and split-levels you see all over Seattle's suburbs. If your top priority is a clean, simple look that’s easy to care for, and historical accuracy isn't a concern, vinyl is a solid, attractive option. It can give an older home an instant, crisp refresh.

The real secret to how they look long-term is how the color is applied. Hardie’s ColorPlus Technology bakes on multiple coats of finish in the factory. Vinyl's color, however, is part of the material itself—it goes all the way through.

Color, Customization, and Long-Term Vibrancy

This difference in color application has a direct impact on how your home will look years down the road.

Hardie ColorPlus™ Technology: That baked-on finish is specifically designed to stand up to UV exposure, which is a huge plus during our surprisingly bright Seattle summers. The colors are curated, look rich, and hold their vibrancy. Plus, if you get tired of the color in a decade, you can have Hardie board professionally repainted, giving you flexibility for the future.

Vinyl's Inherent Color: Because the color runs straight through the material, small nicks and scratches won't show a different color underneath. The downside is that darker vinyl shades can be prone to fading over time, and you can’t really repaint it effectively. If a panel gets damaged years later, finding an exact color match from a new batch can be a real headache.

When you’re stuck in the Hardie board siding vs vinyl debate, your choice really comes down to the identity you want for your home. Hardie offers an unmatched level of authenticity and design flexibility, perfect for elevating your home's architectural character. Vinyl delivers a clean, practical, and uniform look that works beautifully for a wide range of houses.

Making the Final Siding Decision for Your Home

So, after weighing all the pros and cons, how do you actually choose between Hardie Board and vinyl siding? It really boils down to what matters most to you for your home. This isn't just about picking a material; it's about matching your budget, your style, and how much work you're willing to put in down the road.

Let's simplify everything we've talked about—cost, durability, and aesthetics—into a straightforward guide to help you land on the right choice for your Seattle-area home.

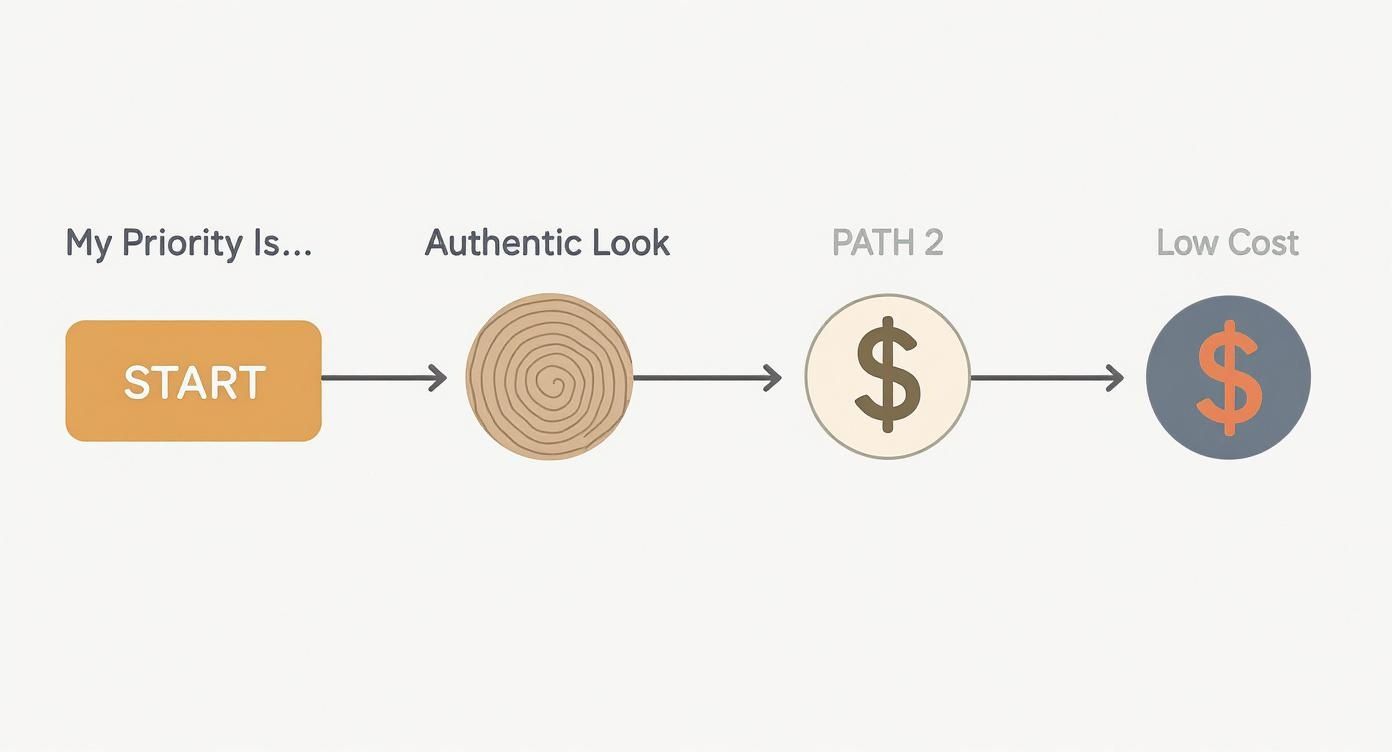

The infographic below offers a great visual starting point, breaking down the decision based on whether you're chasing an authentic, high-end look or need to stick to a tighter budget.

As the chart makes clear, if you’re looking for a premium, long-lasting finish, Hardie Board is probably your answer. But if upfront cost and a speedy installation are your top concerns, vinyl siding is tough to beat.

Situation-Based Recommendations

Think about your specific house. For a home where curb appeal is everything, Hardie Board’s deep, convincing wood grain and factory-applied ColorPlus finish deliver a look that vinyl just can't replicate. It’s built to hold its color and integrity against Seattle’s relentless gray skies and damp weather for decades.

On the other hand, if your project has a strict budget or you need a fast turnaround, vinyl is the practical, logical choice.

- Hardie Board for Heritage Homes: It’s the perfect fit for classic Craftsman or Tudor-style homes where preserving authentic architectural details is non-negotiable. The texture and color stability are unmatched.

- Vinyl for Rental Units: For landlords or property flippers, the low initial investment and simple, inexpensive repairs make vinyl a smart financial decision.

It’s rarely just one factor, though. You have to weigh durability against your budget and the time you're willing to commit to upkeep. For example, if protecting your home from moisture is your number one priority, Hardie Board’s superior resistance to rot, warping, and pests makes it the clear winner.

But if you want a true "set it and forget it" siding that will never need a paintbrush, vinyl’s through-and-through color and low-maintenance nature keep things simple.

"When budget and time are tight, vinyl siding delivers fast results without sacrificing basic weather protection."

Implementation Tips

Ready to move forward? First, take a walk around your property. Note which sides get the most sun or are constantly battered by rain—this helps identify where you need the most robust protection. A siding replacement is also the perfect time to upgrade your home’s insulation, which can lead to significant energy savings.

Next, it's time to get real numbers. Consult with Breeze Siding for tailored estimates that break down the costs for both materials, including the specific labor involved with each.

Finally, lay those quotes and timelines next to the decision tree above. Seeing the numbers side-by-side will help you lock in the solution that truly fits your home and your life.

Here's a simple three-step process to make your choice with confidence:

- Pinpoint your top priorities using the decision tree as a guide.

- Compare detailed, side-by-side quotes from Breeze Siding for both materials.

- Approve the proposal that aligns with your goals and schedule your installation.

Following a structured approach like this removes the guesswork and ensures you'll be happy with your new siding for years to come.

Contact Breeze Siding for expert advice today.

A Few Final Questions on Siding

Even after a side-by-side comparison, it's natural to have a few lingering questions before you pull the trigger on a big project like new siding. When it comes to Hardie board vs. vinyl, these are the questions I hear from homeowners time and time again. Let’s clear up those final details so you can move forward with total confidence.

Does Hardie Board Really Increase Home Value More Than Vinyl?

Absolutely. In a hot market like Seattle, Hardie board almost always provides a better return on investment. While any fresh siding gives your home a facelift, appraisers and savvy buyers see fiber cement as a premium material. It has a solid, substantial look that mimics real wood, signaling quality that can command a higher price.

Vinyl siding, on the other hand, is viewed more as a functional, budget-friendly fix. It definitely improves curb appeal over old, worn-out siding, but it doesn't have that same high-end reputation. If maximizing your home's resale value is a top priority—especially for classic Craftsman homes or more upscale properties—Hardie board is the clear winner.

What Does Long-Term Maintenance Actually Look Like?

The day-to-day upkeep for both is pretty minimal, but their long-term care plans are worlds apart. Knowing what to expect down the road is key.

Vinyl Siding: This is about as low-maintenance as it gets. A yearly wash-down with a soft brush and some soapy water, or a light power washing, is all it takes to keep it looking clean. The real headache comes with damage. If a panel cracks or gets a hole, you have to replace the whole piece, and finding a perfect color match years later can be a real challenge.

Hardie Board Siding: Here, the routine involves checking the caulk lines around windows, doors, and seams every few years to make sure everything is still sealed up tight—a must-do in our rainy Pacific Northwest climate. If you opt for the factory-painted ColorPlus finish, the color holds up incredibly well against fading. If you get the primed version, plan on a new coat of paint every 10-15 years to keep it protected and looking sharp.

The fact that you can repaint Hardie board is one of its biggest selling points. It lets you completely refresh your home's look or even change the color palette entirely—something you just can't do with vinyl.

Can I Paint Vinyl Siding for a New Look?

Technically, you can, but I almost always advise against it. It’s a risky job that comes with a lot of potential downsides. You have to use special, expensive "vinyl-safe" paint, and if the prep work isn't perfect, you'll end up with peeling and bubbling. Worse, dark paint can absorb too much heat and cause the vinyl panels to warp and buckle.

Plus, painting your vinyl siding will void just about any warranty you have on it. If you even think you might want to change your home's color in the future, Hardie board is the much safer, smarter choice. It’s made to be painted, so you know you’ll get a durable, beautiful finish without risking damage to the siding itself.

Ready to get a clear, no-obligation estimate for your Seattle home? The experts at Breeze Siding can walk you through the pros and cons of each material and provide a detailed quote tailored to your specific needs. Start your project with confidence by visiting https://breezesiding.com.